Practice abstract 4

Value chain analysis of Coco baca in Côte d’Ivoire

18 July 2025

Background. Coco baca is a porridge, traditionally from millet. However, due to the high cost of millet, the raw material of Coco baca has now shifted to maize. The Gontougo (Bondoukou) region in northeastern Côte d’Ivoire is traditionally the main production and consumption area for Coco baca.

Objective. The main objective is to provide a general overview of the Coco baca value chain in Cote d’Ivoire and to describe the product process and characteristics.

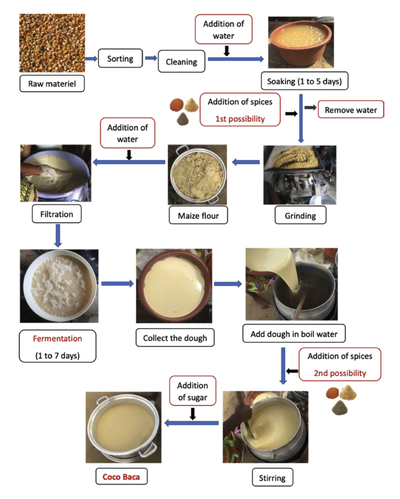

Results. Two production processes coexist: 1/ the traditional process (the most widespread) involves soaking maize or millet grains in water for 1–5 days to extract starch, followed by grinding the grains into flour, which is dissolved in water, filtered and fermented for 24 hours to 7 days at room temperature. After spontaneous fermentation, the starch is diluted and cooked with ingredients like pepper, ginger or anise and cane sugar; 2/ semi-industrial Coco baca is produced the same way but the process ends with a drying step before the product is reduced to powder. Production remains traditional but it incorporates modifications like standardised soaking, fermentation and modern equipment.

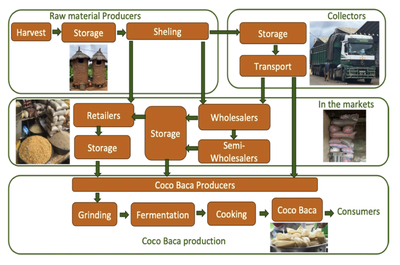

Several safety hazards have been identified throughout the value chain. Mould contamination along maize or millet supply chains, as well as the lack of hygiene along the process. These hazards can be of microbiological origin, mostly due to the contamination and growth of mould (on the cobs and during storage); and to bacterial contamination from inadequate hygiene practices during transformation. Two case studies consisting in two groups of interconnected business operators within the Coco baca value chain have been selected.

Recommendations. An in-depth analysis of the selected case studies, based on a precise multi- dimensional approach by a multidisciplinary team —including socio-economists, microbiologists and food technologists—will lead to recommendations.